The Importance of Glass Edge Processing: Understanding Chamfering and Polishing Technique

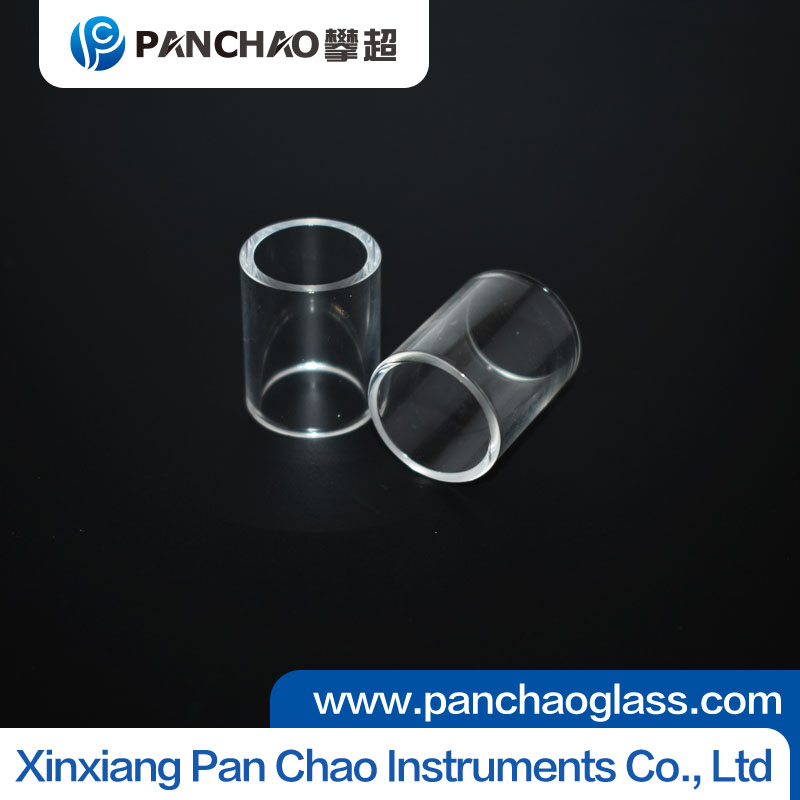

Glass edge processing is a crucial finishing step that directly affects the strength, safety, and durability of sight glass, viewing windows, and precision glass tubes. Properly treated edges reduce the risk of cracking, improve handling safety, and enhance the overall performance of the glass in demanding applications. Two of the most essential techniques are chamfering and polishing.

1. Why Edge Processing Matters

Raw-cut glass edges are typically sharp, uneven, and full of micro-cracks caused by mechanical cutting. These microscopic defects concentrate stress, making the glass highly vulnerable to breaking under pressure or thermal shock. Edge finishing eliminates these weak points, significantly increasing the glass’s resistance to impact, vibration, and temperature changes.

2. Chamfering (Beveling) Technique

Chamfering involves removing sharp corners and creating a smooth, angled edge. This process:

-

Reduces stress concentration points

-

Prevents accidental injuries during installation

-

Improves compatibility with gaskets and metal frames

-

Helps distribute load more evenly when the glass is mounted

Chamfer angles can vary from small micro-bevels for optical applications to wider bevels for industrial sight glasses that require extra mechanical strength.

3. Polishing Technique

Polishing further refines the chamfered edges, removing fine scratches and achieving a smooth, glossy surface. Polished edges significantly enhance:

-

Strength – by eliminating micro-cracks

-

Safety – by reducing sharpness

-

Aesthetic quality – important for instruments or viewing panels

-

Chemical resistance – smoother edges resist corrosion better in harsh environments

Techniques include mechanical polishing, fire polishing, and cerium oxide fine polishing, depending on clarity and tolerance requirements.

4. Industrial Importance

For high-pressure sight glasses, laboratory glass tubes, and custom optical components, proper edge processing is not optional—it is a critical safety measure that determines the product’s lifespan and reliability.

Conclusion

Chamfering and polishing transform fragile cut edges into strong, durable, and safe surfaces. High-quality edge treatment ensures better performance, longer service life, and safer operation across both industrial and scientific applications.

Related articles

- Applications and Processing Considerations of Thick-Walled Gl

- Challenges in Quartz Glass Processing: High-Temperature Melti

- Differences and Connection Methods Between Glass Windows and

- Common Problems and Solutions in Custom Non-Standard Sight Gl

- Custom Glass Tube Manufacturing Process: From Cutting to Fire

- Safety of Tempered Sight Glass: Impact Resistance Testing Exp

- Light Transmittance Testing and Applications of Quartz Glass

- Thermal Stability of Borosilicate Glass: Why It’s the Indus

- Sight Glass Selection Guide for High-Temperature Environments

- Comparison of Borosilicate, Quartz, and Tempered Glass: Three

Xinxiang Pan Chao Instruments Co., Ltd.

Tel: +86 13343800331

Contact person:Carrie Niu

Fax: 0373 303 0331

Email:sales@panchaoglass.com